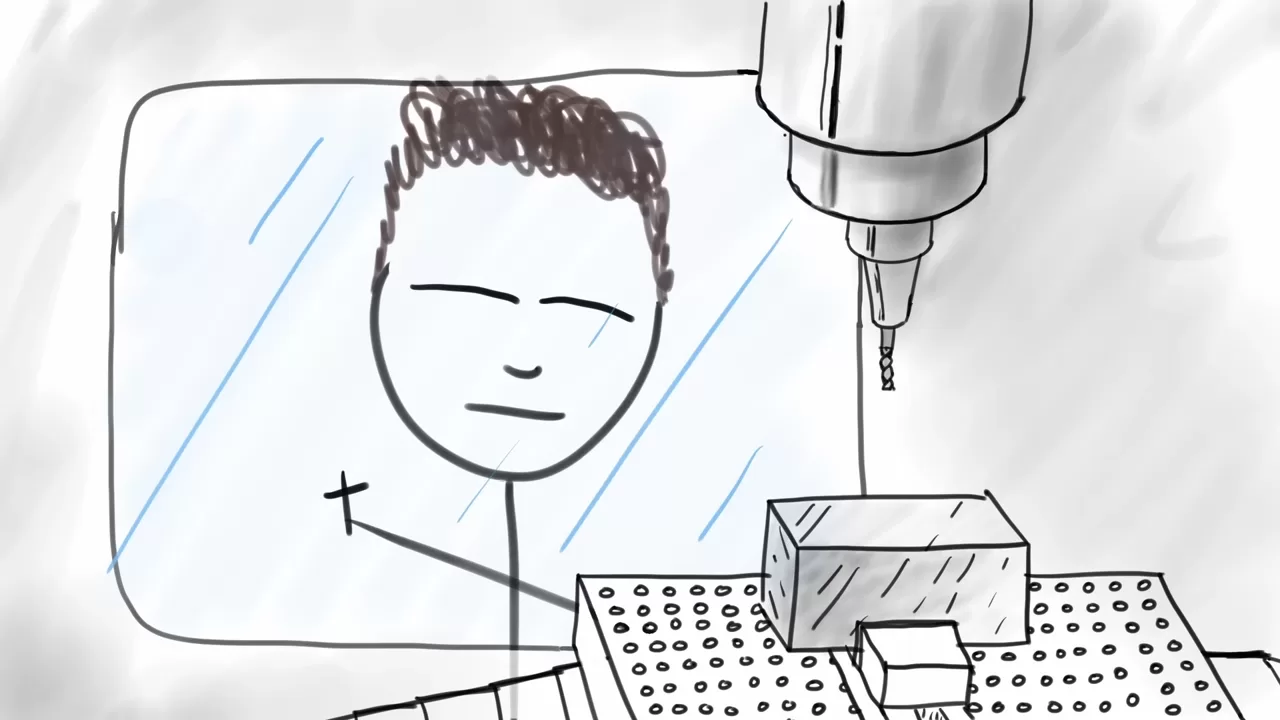

In modern woodworking and furniture manufacturing, precision and consistency are key factors in ensuring high-quality outcomes. This is especially true when working with engineered wood products such as MDF, which is widely used for interior panels, furniture fronts, and decorative components. Among the various processing methods, mdf cnc cutting has become one of the most efficient and reliable techniques, allowing for the creation of detailed and repeatable designs.

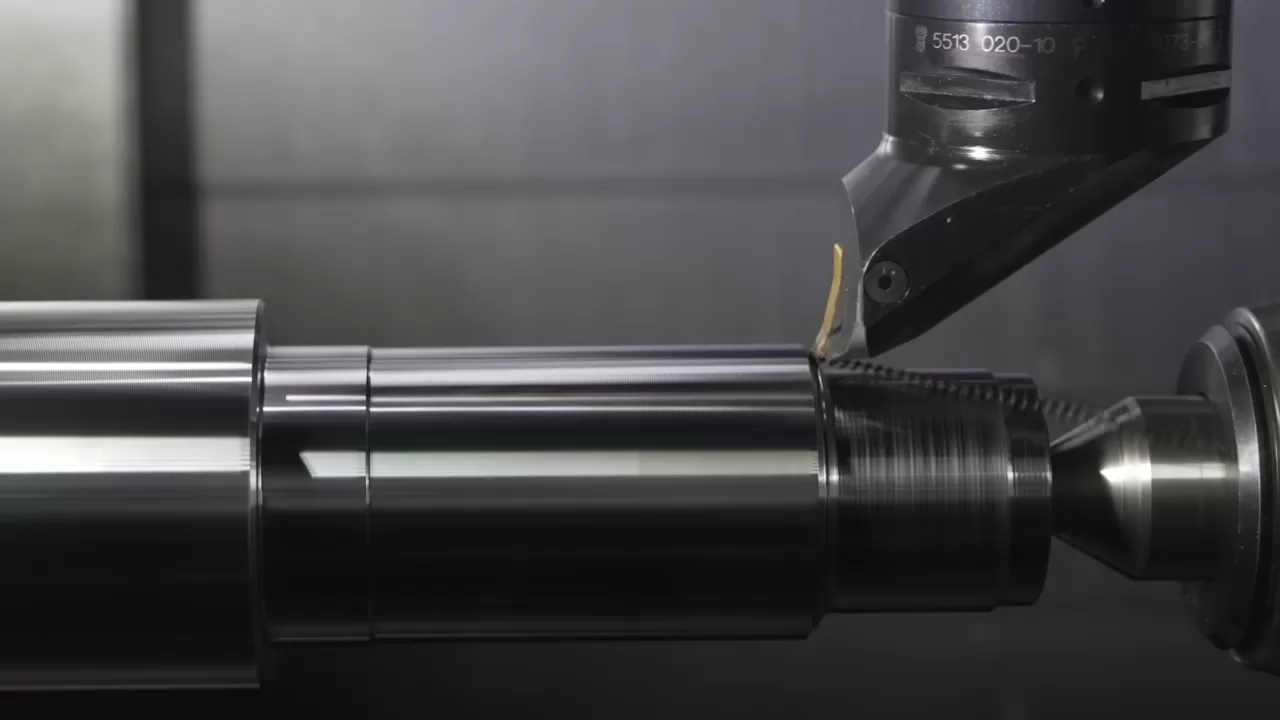

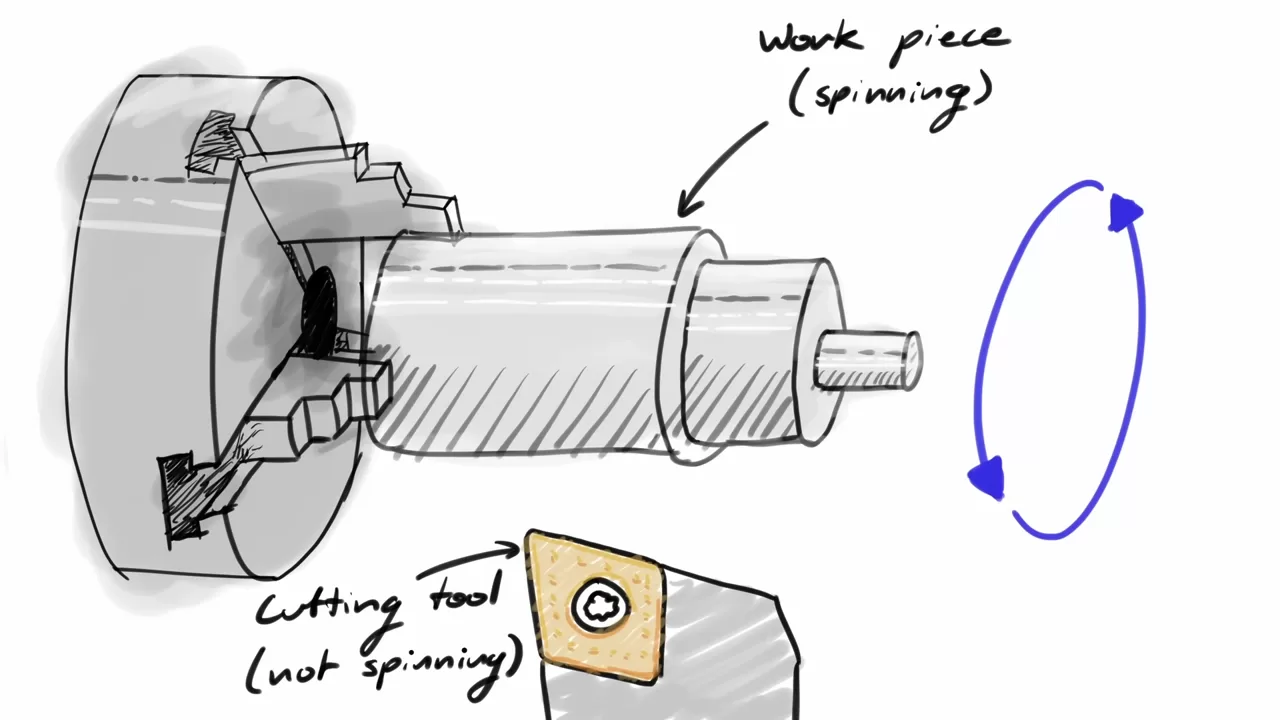

CNC (Computer Numerical Control) machining enables highly accurate operations through pre-programmed digital instructions. It eliminates many manual errors and significantly reduces production time. This is particularly beneficial in situations where identical components need to be produced in bulk, or when complex patterns are required that would be challenging to achieve by hand.

MDF (Medium-Density Fibreboard) is an ideal material for CNC cutting. Its homogeneous structure—made from fine wood fibers bonded with resin under heat and pressure—means it can be milled cleanly without splintering or tearing. Edges remain smooth after cutting and often require minimal finishing. This makes MDF particularly suitable for fine detailing and intricate work.

CNC routers can be programmed to produce everything from simple shapes to highly ornate carvings. Whether creating custom cabinet fronts, wall panels, signage, or decorative screens, the flexibility of CNC technology allows for a high degree of customization. Design software enables users to control cutting depth, spindle speed, tool path, and tool selection, adapting each job to its specific requirements.

Efficiency is another major advantage. A single operator can oversee several machines or projects simultaneously, maximizing productivity. Moreover, digital workflows allow for thorough planning—users can estimate material usage, cutting time, and dimensions before actual production begins, which reduces waste and optimizes resources.

Beyond large-scale manufacturing, CNC cutting is also valuable for bespoke or small-batch production. Designers and architects often rely on this technology to realize unique interior solutions, such as perforated partitions, decorative ceiling tiles, or branded elements for commercial spaces. The ability to accurately replicate digital patterns means that even one-off designs can be produced with high fidelity.

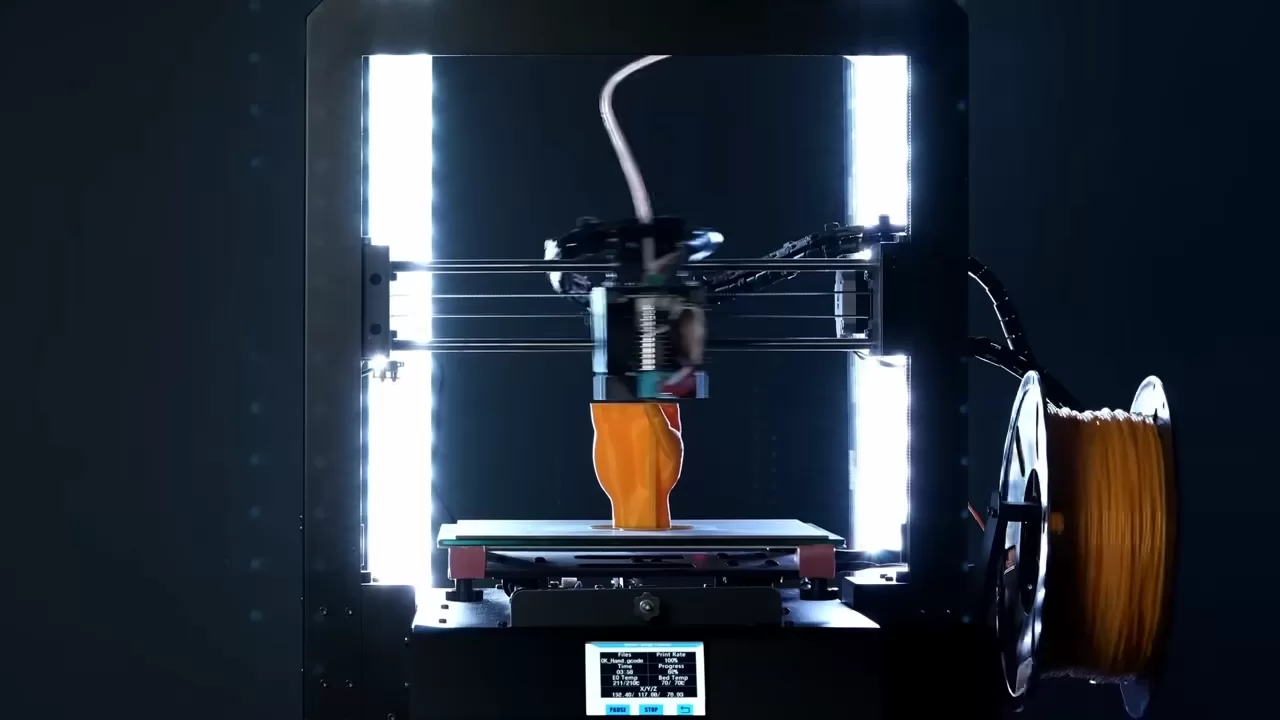

The development of CNC technology, combined with the versatility of MDF, has transformed many aspects of modern fabrication. What was once time-consuming and labor-intensive can now be accomplished quickly and consistently using automated processes. This evolution has opened new creative possibilities for industries ranging from furniture and construction to advertising and art installations.

In summary, MDF CNC cutting represents a perfect intersection of material and technology. It empowers manufacturers, craftsmen, and designers to bring their ideas to life with speed, precision, and flexibility—setting new standards in quality and innovation.