Toolboxes are an essential part of any workshop, garage, or professional workspace. But have you ever wondered how they’re made? From raw steel to a finished product ready for your tools, the process involves precision engineering, advanced manufacturing, and high-quality craftsmanship. In this article, we’ll take a behind-the-scenes look at how toolboxes, like those from Craftsman, are created from start to finish.

Step 1: The Arrival of Raw Steel

The manufacturing process begins with the delivery of steel coils, which serve as the raw material for toolboxes. These steel coils arrive at the factory in massive shipments, often weighing over 24,000 pounds each—the equivalent of six passenger cars! The coils are unwrapped and fed into a slitting machine, which slices them into smaller strips, ready for further processing.

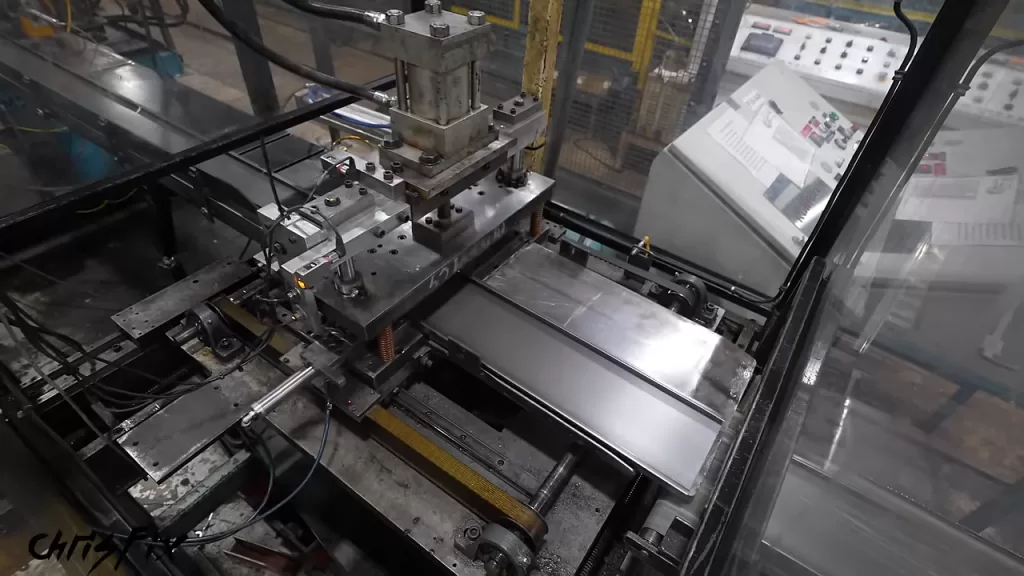

Step 2: Stamping and Shaping the Metal

Once the steel is cut into manageable pieces, it moves to the stamping press, where over 200 tons of pressure is applied to punch holes and cut the metal into precise drawer and box components. This ensures every piece fits together perfectly later in the process. Each sheet is inspected for accuracy using laser measurement systems to ensure it meets strict quality standards.

Step 3: Forming the Drawers and Box

The individual components, including the drawers and main toolbox structure, are shaped using several techniques:

- Brake bending: This process creates the sides of the drawers by bending the sheet metal at precise angles.

- Roll forming: The front of each drawer is shaped with a smooth, curved edge to allow for easy opening and closing.

- Spot welding: Using over 5,000 amps of electricity, the parts are welded together to create a durable, long-lasting structure.

Step 4: Assembling the Toolbox Frame

With the drawers complete, it’s time to build the main toolbox shell. The back, sides, top, and bottom of the toolbox are welded and riveted together to form a solid frame. This structure undergoes several reinforcement processes, including:

- Adding internal supports for drawer sliders

- Mounting the lock rods to secure the drawers

- Installing metal braces to provide extra support for the wheels

Step 5: The Advanced Painting Process

One of the most critical steps in manufacturing toolboxes is the painting process. Instead of using traditional spray painting or powder coating, electrophoresis coating (E-coating) is used. This technique involves:

- Cleaning the metal using a seven-stage washing process to remove dirt, oil, and contaminants.

- Submerging the toolbox in an electrically charged paint bath—positively charged paint particles bond to the negatively charged metal, ensuring an even coat.

- Baking the paint at 400°F to create a durable, chip-resistant finish.

This method is more efficient, environmentally friendly, and long-lasting than traditional painting techniques.

Step 6: Final Assembly and Quality Control

After the paint has cured, the toolbox is assembled and prepared for shipping:

- Locks and branding: The Craftsman logo, lock mechanism, and safety stickers are applied.

- Drawer installation: Workers carefully slide the drawers into place and secure them with rivets.

- Quality inspection: Each toolbox undergoes a final comprehensive check to ensure the drawers open smoothly, the locks function properly, and there are no defects in the paint or structure.

Step 7: Packaging and Shipping

Once the toolbox passes its final inspection, it is packaged securely in custom-fit cardboard boxes with protective foam padding to prevent damage during transport. Forklifts load the completed toolboxes onto trucks, ready to be shipped to stores and customers.

Why Craftsman Toolboxes Stand Out

Unlike many other toolboxes made overseas, Craftsman toolboxes are manufactured in the USA, ensuring high-quality materials and precise craftsmanship. Their use of E-coating for durability, reinforced structures for longevity, and affordable pricing make them a top choice for both professionals and beginners.

Final Thoughts

The next time you open your toolbox, take a moment to appreciate the engineering and craftsmanship that went into making it. From raw steel to finished product, each step in the process is meticulously designed to create a durable, reliable, and high-quality storage solution for your tools.

If you’re looking for a great toolbox for your garage or workshop, consider a Craftsman toolbox—now that you know exactly how they’re made!