Insert molding is an advanced manufacturing solution that stands at the intersection of material science and mechanical engineering. It is the process of integrating pre-formed components—known as inserts (often metal, ceramic, or electronic elements)—into a plastic part during the standard injection molding cycle.

This technique is not merely about encasing an object; it is about creating a single, highly functional, and mechanically superior component where the insert becomes an integral part of the final product. Insert molding is crucial for applications that demand enhanced strength, conductivity, threading, or precise mounting features, making it a foundational process in the automotive, medical device, and consumer electronics industries.

This comprehensive guide delves into the mechanisms, profound benefits, critical design principles, and essential considerations for successfully implementing an Insert Molding Solution to achieve manufacturing excellence and component consolidation.

Defining Insert Molding Solutions

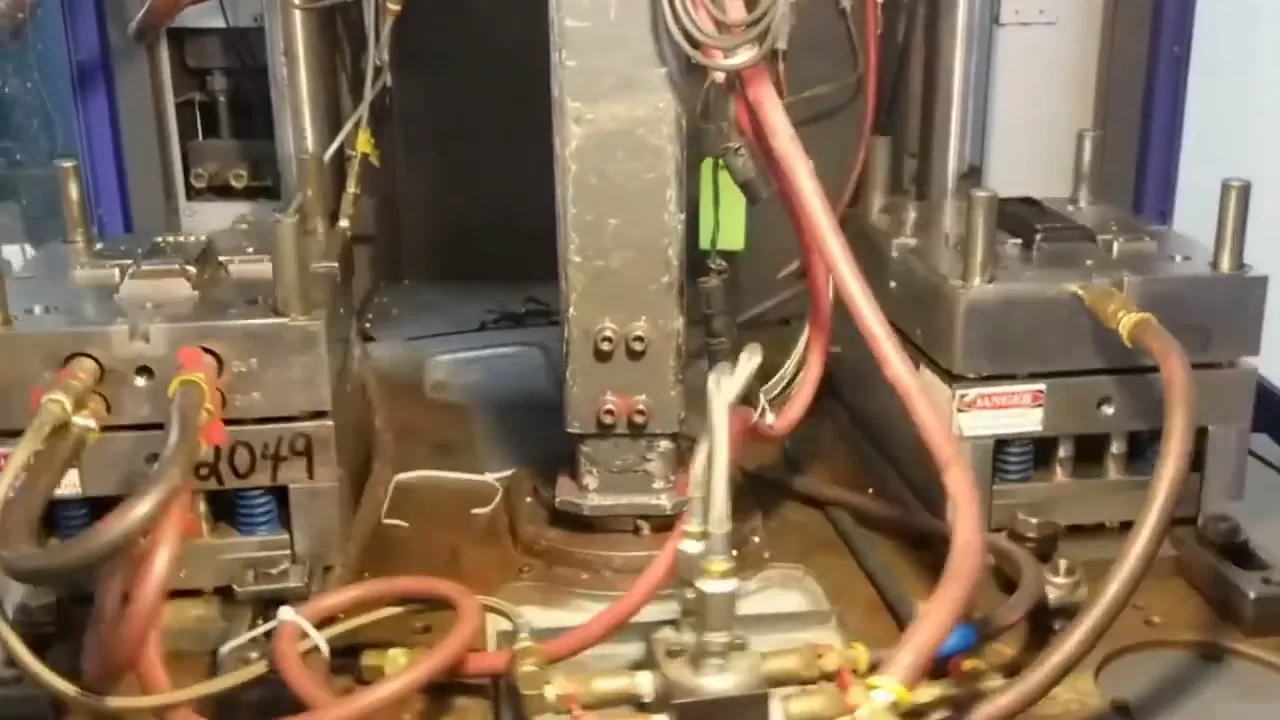

In insert molding, the tooling is designed not just to form the plastic, but also to precisely hold the non-plastic insert in place within the mold cavity.

The Mechanism: A Step-by-Step Overview

- Insert Preparation: The pre-formed component (the insert) is manufactured. This could be a metal screw, a threaded bushing, a circuit board, or a sensor.

- Insert Placement: The insert is manually or robotically placed into the open mold cavity. The mold typically features pins, clips, or a core that holds the insert securely against the high pressure of the injection process.

- Mold Clamping: The mold is closed, clamping the insert firmly in position.

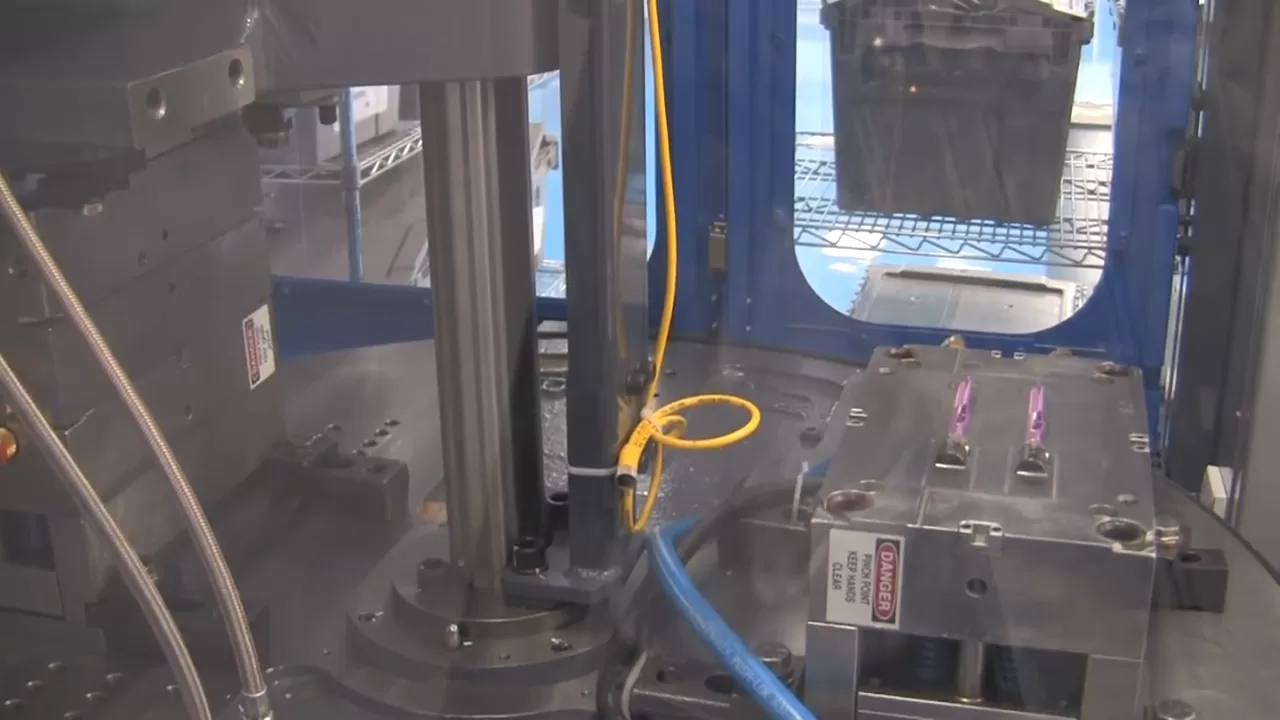

- Resin Injection: Molten thermoplastic resin is injected into the cavity, flowing around and encapsulating the insert.

- Cooling and Ejection: The plastic cools and solidifies. The mold opens, and the final, unified component is ejected, with the insert permanently secured.

Why Integration Matters

The primary value of insert molding is component consolidation. By eliminating the need for subsequent assembly steps (like pressing in metal nuts or epoxying circuit boards), manufacturers achieve a lighter, stronger, and more cost-effective final product with zero potential for the insert to loosen or rotate.

Strategic Advantages of Insert Molding Solutions

Leveraging insert molding delivers substantial functional and economic returns that surpass traditional manufacturing methods:

1. Superior Mechanical Strength and Reliability

Encapsulating metal inserts (like threaded studs or bushings) within the plastic matrix creates a much stronger pull-out resistance and torsional strength than post-molding assembly methods (such as heat staking or ultrasonic welding). The plastic shrinks tightly around the insert, forming a powerful mechanical interlock.

2. Enhanced Functionality and Performance

Insert molding allows for the direct integration of non-plastic functions:

- Conductivity: Embedding metal terminals or connectors for electrical circuits.

- Thermal Management: Integrating metal heat sinks for efficient heat dissipation.

- Aesthetics: Molding around decorative metal logos or panels.

3. Component and Assembly Cost Reduction

The most compelling economic benefit is realized through assembly elimination. By fusing two or more parts into one during the molding cycle, businesses save on labor, adhesives, secondary tooling, and the complexities of managing multiple assembly lines.

4. Miniaturization and Precision

Insert molding enables the production of smaller, lighter assemblies. The high precision of the tooling ensures that integrated pins, threads, and electrical contacts are positioned with extremely tight dimensional tolerances, crucial for modern, densely packed electronic devices.

5. Improved Durability and Environmental Sealing

When used in conjunction with overmolding techniques, insert molding can integrate sensitive electronics (like sensors or batteries) and then seal them completely with an external plastic layer, offering exceptional protection against moisture, dust, and vibration.

Design for Manufacturing (DFM) for Insert Molding

The success of an insert molding solution relies entirely on meticulous DFM planning, particularly concerning insert design and tooling strategy.

A. Insert Design Requirements

The insert itself must be designed to promote the strongest possible bond with the plastic:

- Knurling and Grooves: Metal inserts should feature roughened or patterned surfaces (like diamond knurling or annular grooves) that provide anchor points for the molten plastic to flow into and physically lock onto.

- Preventing Rotation: Hexagonal or square geometry on the insert’s body is highly effective at preventing the insert from rotating within the plastic shell when torque is applied.

- Stress Management: Sharp edges on the insert should be avoided as they can create high stress concentration points in the surrounding plastic, leading to cracking (stress cracking) over time or during cooling.

B. Tooling and Processing Considerations

The mold design must account for the presence and safe handling of the insert:

- Retention Features: The mold cavity must incorporate precise pins, shutoffs, or spring-loaded features to hold the insert securely against the extreme pressure of the injection process. If the insert shifts, it can damage the mold.

- Draft and Gate Placement: The gate (where the plastic enters) must be placed carefully to ensure the molten resin flows around the insert smoothly without causing the insert to shift or warp.

- Venting: Ensuring adequate venting is critical, especially around complex inserts, to prevent air traps that lead to incomplete fills (short shots) or localized scorching.

- Material Selection: The plastic resin must be compatible with the insert’s thermal properties. If the metal insert is much cooler than the resin, it can cause the resin to solidify prematurely, resulting in poor flow or weak weld lines.

Material Pairings and Thermal Management

Thermal compatibility between the metal insert and the surrounding plastic is a critical, often overlooked, challenge.

Coefficient of Thermal Expansion (CTE) Mismatch

Metal inserts have a significantly different Coefficient of Thermal Expansion (CTE) than plastic resins. As the part cools from the high molding temperature to room temperature, the metal shrinks much less than the plastic. This differential shrinkage can induce massive internal stress in the plastic surrounding the insert.

Solution Strategies:

- Resin Selection: Use resins with lower mold shrinkage rates (e.g., specific grades of liquid crystal polymers or glass-filled resins).

- Design Buffer: Increase the wall thickness of the plastic surrounding the insert to better distribute the internal stress.

- Pre-heating Inserts: In some critical applications, metal inserts are pre-heated to minimize the temperature differential during molding, thus reducing stress.

Common Insert Materials

| Insert Material | Typical Function | Critical Benefit |

| Brass/Steel | Threaded inserts, bolts, electrical contacts. | High mechanical strength; permanent threading solution. |

| Copper/Aluminum | Bus bars, heat sinks, electrical terminals. | Superior electrical and thermal conductivity. |

| PCBs/Flex Circuits | Sensors, LEDs, antennas. | Integration of electronic function; permanent sealing. |

| Ceramics/Glass | Lenses, specialized sensor protection. | High resistance to heat and chemicals. |

Selecting the Right Insert Molding Partner

The specialized nature of insert molding requires a partner with significant technical expertise beyond standard molding:

- Automation and Robotics: For high-volume projects, the molder must possess advanced robotic systems (pick-and-place) for accurate and rapid insert loading, which is key to maintaining low cycle times and consistent quality.

- Tooling Precision: Demonstrated expertise in building molds with high-precision retention features and complex shut-offs to prevent flash around the insert.

- Quality Control: Experience with dimensional inspection of inserts pre-molding and rigorous testing of the final parts (e.g., pull-out force testing) to validate the mechanical bond strength.

Conclusion: The Future is Integrated

Insert molding injection molding is a powerful, non-negotiable solution for creating modern assemblies that demand the combined performance of multiple materials. By permanently fusing metal, electronics, and plastic in a single, highly efficient process, manufacturers can achieve unparalleled levels of mechanical integrity, miniaturization, and cost reduction.

Mastering the DFM principles—particularly insert design and thermal stress management—is the definitive path to leveraging this technology for competitive advantage and ensuring the long-term reliability of your integrated components.