In modern construction, engineering, and even everyday life, it is impossible to imagine work without bolts. These simple yet crucial elements ensure the strength of joints, the safety of structures, and the durability of equipment. Among the many varieties, stainless steel bolts stand out as a universal solution thanks to their unique properties.

Why Stainless Steel?

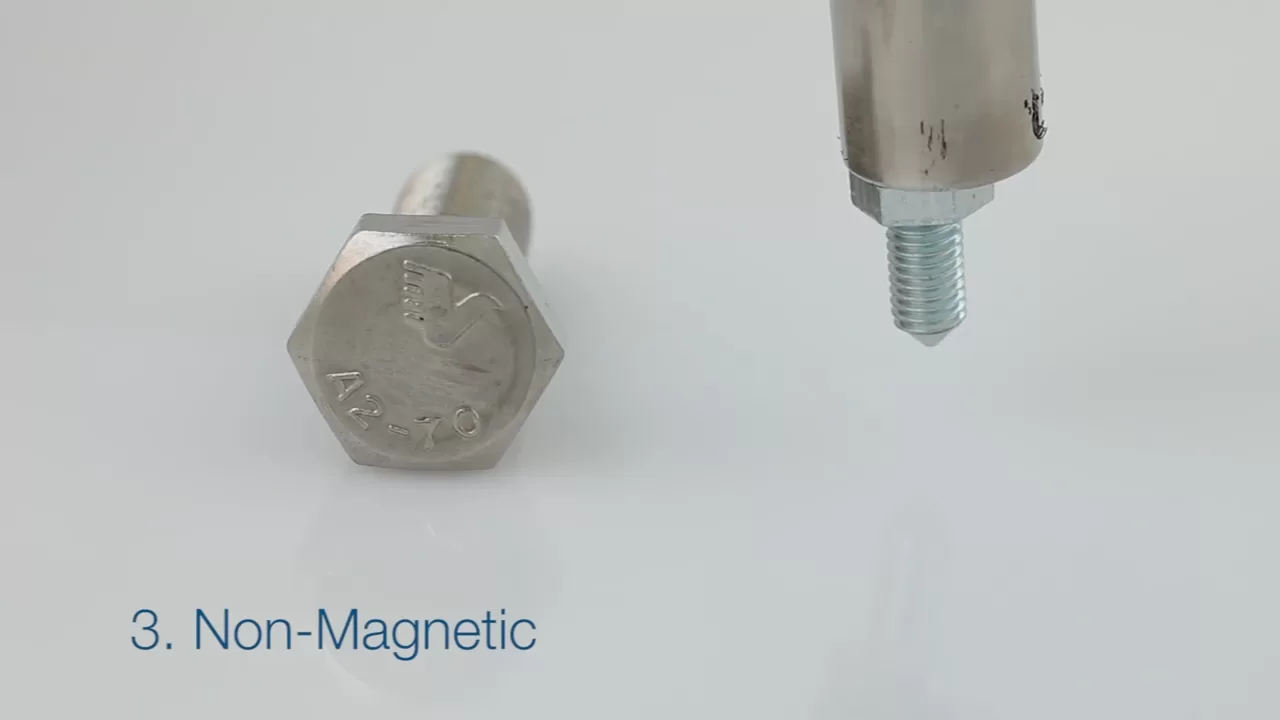

Stainless steel is an alloy containing chromium, which provides protection against corrosion. Combined with elements like nickel, molybdenum, and manganese, it not only resists rust but also maintains strength in extreme environments.

Key advantages of stainless steel bolts include:

- Corrosion resistance – they remain intact even in harsh environments such as seawater or acidic conditions.

- Durability – they last for decades without losing mechanical properties.

- Versatility – widely used in construction, industry, medicine, and household projects.

- Aesthetic appeal – the polished surface looks neat and fits perfectly in visible joints.

Common Types of Stainless Steel Bolts

Depending on their design and strength class, stainless steel bolts can be grouped into several categories:

- Hex bolts – the standard option for most construction and industrial uses.

- Countersunk bolts – perfect for furniture and decorative applications where a smooth surface is desired.

- Anchor bolts – essential for fixing heavy structures to concrete bases.

- High-strength bolts – designed for automotive, aerospace, and heavy machinery industries.

Every type follows strict international standards (ISO, DIN, GOST), ensuring safety and reliability.

Where Are They Used?

Stainless steel bolts are valued across numerous fields:

- Construction – for joining steel structures, roofing, and façade systems.

- Mechanical engineering – vital for engines, assemblies, and high-load components.

- Food industry – used in processing equipment where hygiene and durability are essential.

- Medicine – applied in surgical tools and medical devices.

- Shipbuilding – perfect for parts exposed to seawater and humidity.

In all these areas, stainless steel fasteners guarantee reliability where ordinary bolts would quickly fail.

Why Quality Matters

Using poor-quality fasteners may cause structural damage, equipment breakdowns, or even accidents. Choosing certified stainless steel bolts is an investment in safety and long-term performance.

For a detailed breakdown of their properties and applications, check out this comprehensive article:

👉 https://english-letter.ru/publ/stati/raznoe/bolty_iz_nerzhavejushhej_stali_svojstva_vidy_i_sfery_primenenija/20-1-0-321.