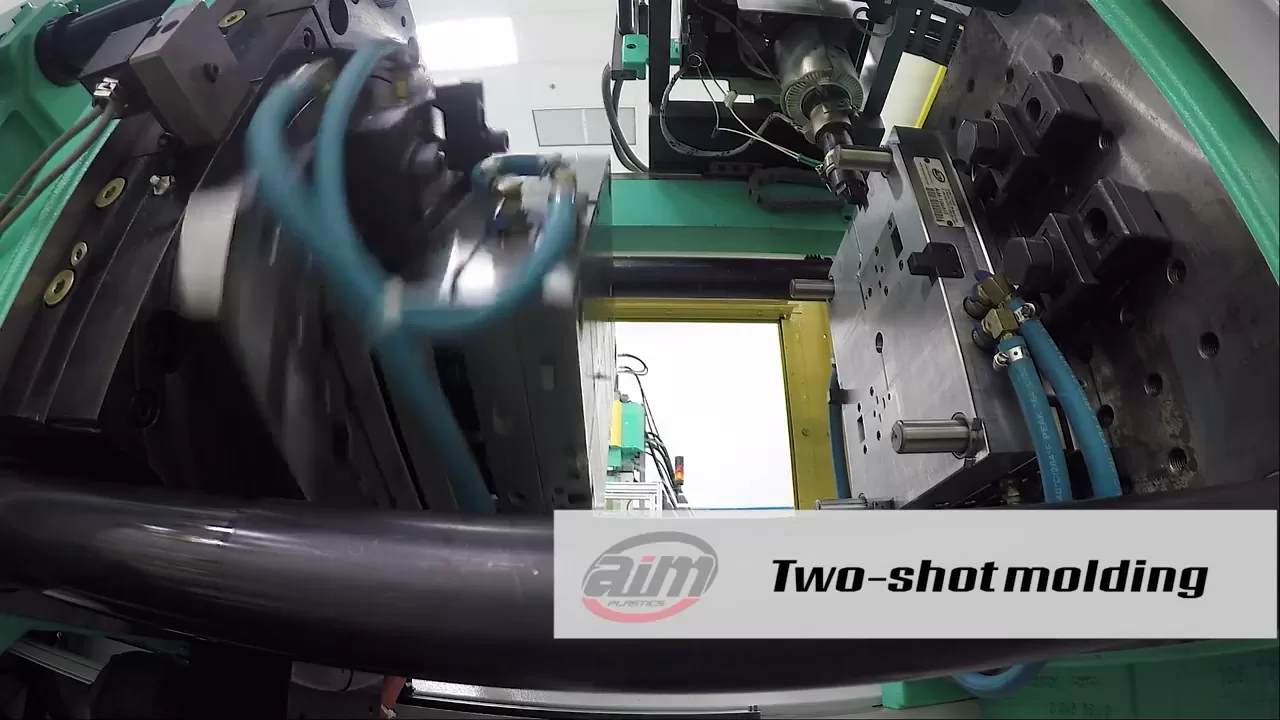

Injection machine moulding is one of the most widely used manufacturing processes for producing plastic parts with high precision, repeatability, and efficiency. From automotive components and medical devices to packaging and consumer goods, injection moulding machines play a critical role in modern industrial production.

This article explains what injection machine moulding is, how it works, the key machine types, benefits, applications, and factors that affect part quality.

What Is Injection Machine Moulding?

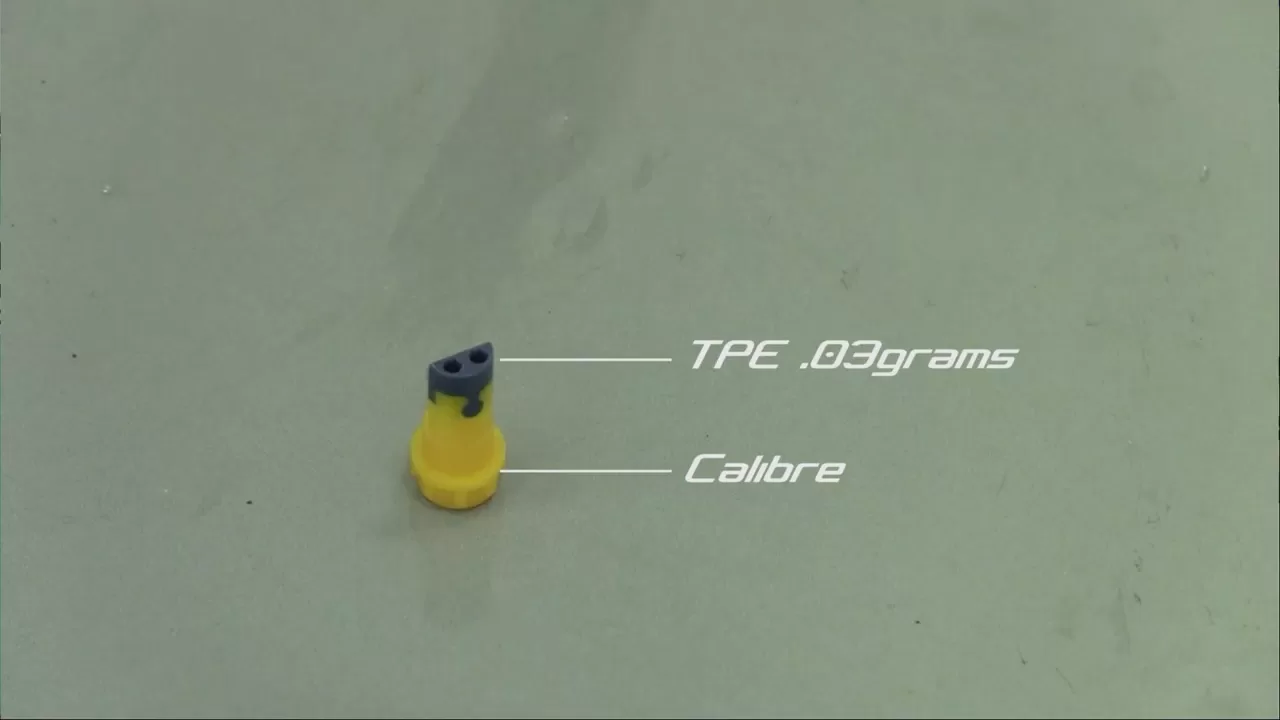

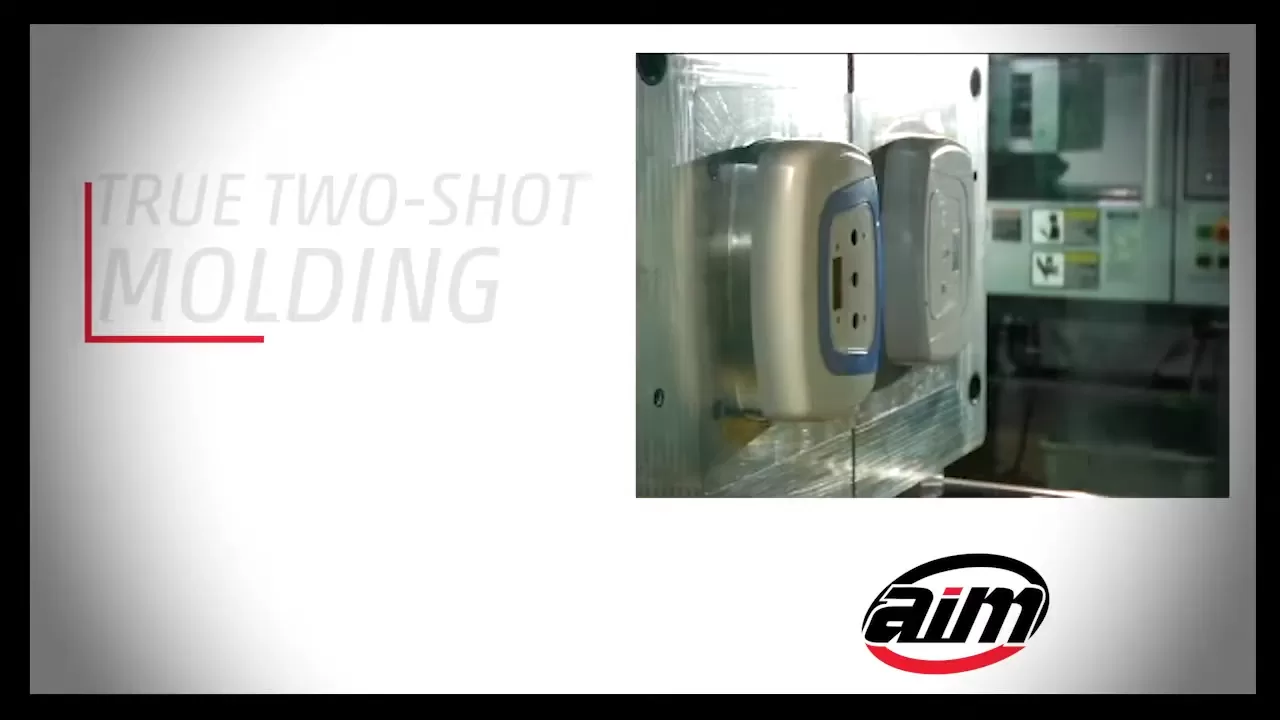

Injection machine moulding service provided by AIM Plastic is a process where molten plastic is injected into a mould cavity under high pressure, allowed to cool and solidify, and then ejected as a finished part. The process is highly automated and ideal for both low- and high-volume production.

An injection moulding machine consists of three main systems:

- Injection unit

- Clamping unit

- Control system

Together, these components ensure accurate material flow, consistent pressure, and repeatable production cycles.

How Injection Machine Moulding Works

The injection moulding process follows several precise steps:

- Material Feeding

Plastic pellets are fed into the machine hopper. - Melting and Plasticising

The screw rotates inside a heated barrel, melting and homogenising the material. - Injection

The molten plastic is injected into the closed mould cavity at a controlled speed and pressure. - Holding and Packing

Pressure is maintained to compensate for material shrinkage. - Cooling

The part cools and solidifies inside the mould. - Ejection

The mould opens and ejector pins release the finished part.

This cycle repeats automatically, enabling consistent mass production.

Types of Injection Moulding Machines

Hydraulic Injection Moulding Machines

These machines offer high clamping force and durability, making them suitable for large parts and heavy-duty applications.

Electric Injection Moulding Machines

Electric machines provide:

- High precision

- Energy efficiency

- Faster cycle times

They are commonly used in medical, electronics, and precision molding.

Hybrid Injection Moulding Machines

Hybrid machines combine hydraulic power with electric control, balancing performance and energy savings.

Key Advantages of Injection Machine Moulding

Injection machine moulding offers several important benefits:

- High-dimensional accuracy

- Excellent surface finish

- Consistent part quality

- Low material waste

- Fast production cycles

- Ability to mold complex geometries

Once the mould is built, the cost per part becomes very low, especially for high-volume production.

Common Materials Used in Injection Machine Moulding

Injection moulding machines process a wide range of thermoplastics, including:

- Polypropylene (PP)

- ABS

- Polyethylene (HDPE, LDPE)

- Polycarbonate (PC)

- Nylon (PA)

- PEEK and other engineering plastics

Material selection depends on strength, temperature resistance, chemical stability, and end-use requirements.

Applications of Injection Machine Moulding

Injection machine moulding is used across many industries:

- Automotive: interior trims, housings, connectors

- Medical: syringes, device housings, disposables

- Packaging: caps, containers, closures

- Electronics: enclosures, connectors, precision parts

- Consumer goods: household products, tools, toys

Its versatility makes it essential for modern manufacturing.

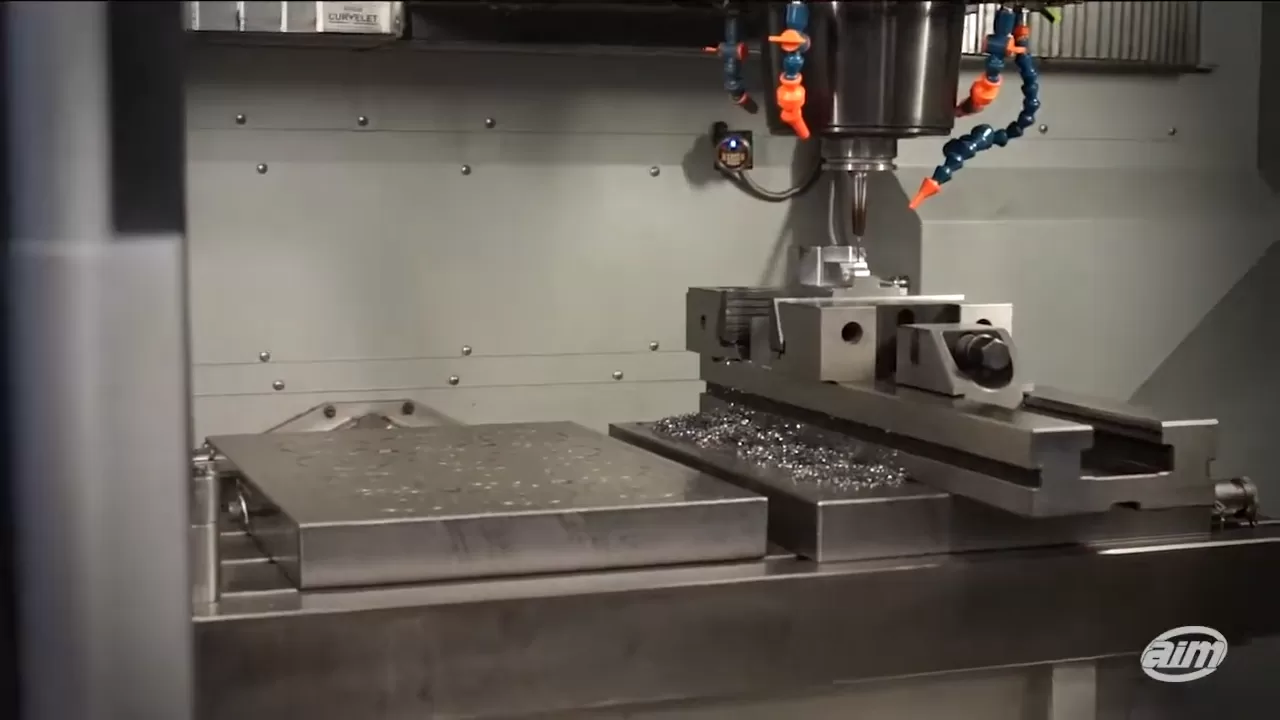

Factors That Affect Injection Moulding Quality

Several factors influence the success of injection machine moulding:

- Proper machine sizing

- Stable injection parameters

- Effective mould cooling

- Material drying and handling

- Regular machine and mould maintenance

Optimising these elements helps reduce defects such as warpage, sink marks, flash, and short shots.

Conclusion

Injection machine moulding is a reliable, efficient, and scalable manufacturing process for producing high-quality plastic parts. By choosing the right injection moulding machine, optimising process parameters, and maintaining tooling and equipment, manufacturers can achieve consistent production with minimal waste and maximum efficiency.

As industries continue to demand precision, speed, and cost control, injection machine moulding remains a cornerstone of plastic manufacturing worldwide.