In the modern competitive environment, the ability to stand out can be determined by innovation, quality and clever design, and custom molded plastic products provide each one of them. Way beyond simple containers or packaging, bespoke plastics are now defining the shape of smooth consumer products to rough industrial components, with no greater flexibility to offer companies seeking to streamline production, branding and sustainability.

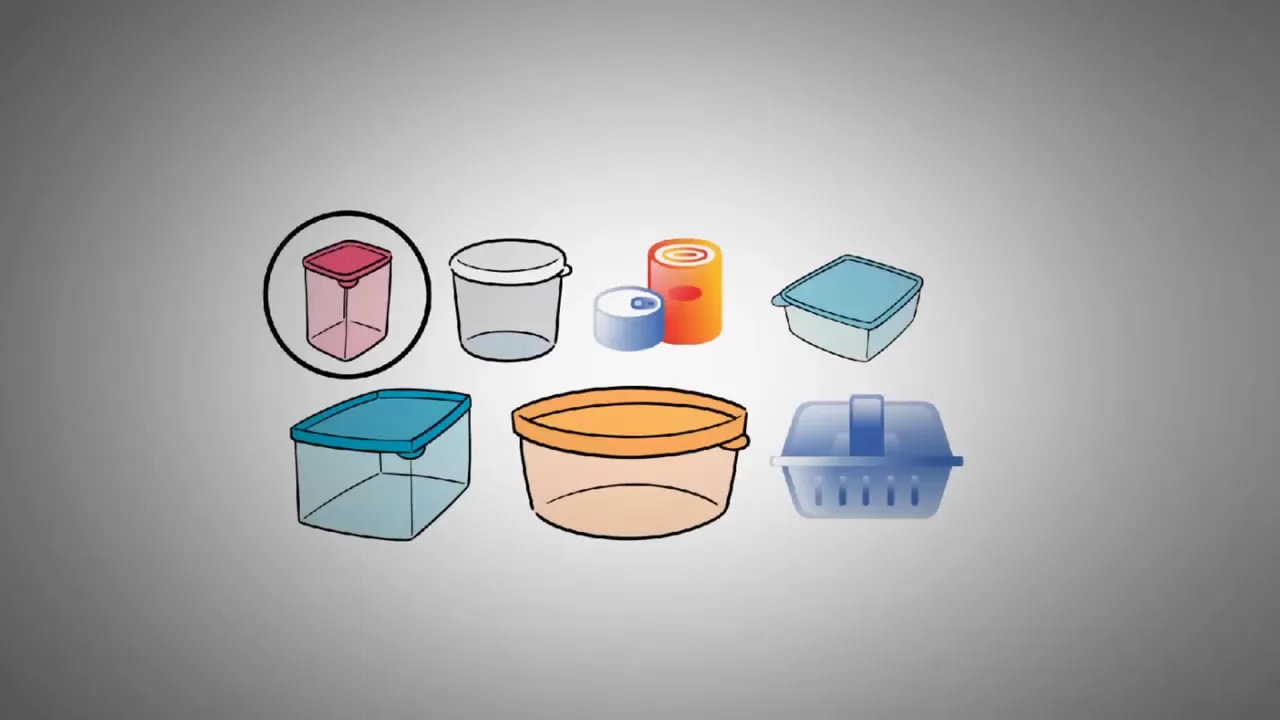

Understand the Strength of Custom Plastics

Plastic is light, strong and flexible. Replacing generic with custom plastic parts allows companies to obtain more precise tolerances, customized thickness, and distinctive finishes that correspond to brand identity and product requirements. Be it the creation of small mechanical components, or the creation of high-end consumer packaging, custom plastics not only save on waste, but also create better fit and enhance appeal.

Maximize Usability and Workflow

Tailored plastic products ensure that your products are easy to use and more efficient to assemble. Careful consideration, such as ergonomic grips or inbuilt clips, or cable slots can be formed into each part. Such optimizations streamline processes, reduce manufacturing time, and ensure flawless consistency throughout all production lines – optimal with startups and large volume manufacturers.

Create a better Brand Name

Plastic presents unlimited branding opportunities. To make memorable designs, you can insert logos, match signature colours or play with matte and glossy finishes. Your brand image is strengthened even with small branded items such as trays, cases, or promotional bottles that remind your customers of you. Every piece of custom plastic turns into the visible part of your personality.

Reduce Expenses and Enhance Effectiveness

Customisation is not necessarily more expensive. Using plastics with different sizes allows you to manufacture only a specific quantity and size that fits your exact process, remove unused parts, and enhance inventory control. Scalability Once you have custom molds, it is simple to scale up- to produce thousands of the same part with little waste and reduced per unit costs.

Enhance Durability and Quality

The selection of materials guarantees durability and dependability. Examples of engineering plastics include ABS, polycarbonate, polypropylene, etc., and they combine flexibility, resistance to wear, and strength. Give customers products that last, and you gain trust, reduce returns, and, most importantly, improve your reputation and bottom line.

Make Flexible with Flexible Manufacturing

With 3D printing and rapid prototyping, allow you to test ideas quicker and change designs at high speeds. Companies are now capable of responding to market trends or regulatory changes with minimum downtime. Custom plastic manufacturing makes your product line responsive whether it is adapting to new standards of safety or updating a design.

Adopt sustainable alternatives

As the need to make products environmentally friendly increases, recycled resins and bioplastics have emerged as differentiation powerhouses. They are sustainable and less harmful to the environment. By sharing these activities publicly, you will find interested customers who are environmentally friendly and present your brand as accountable and progressive.

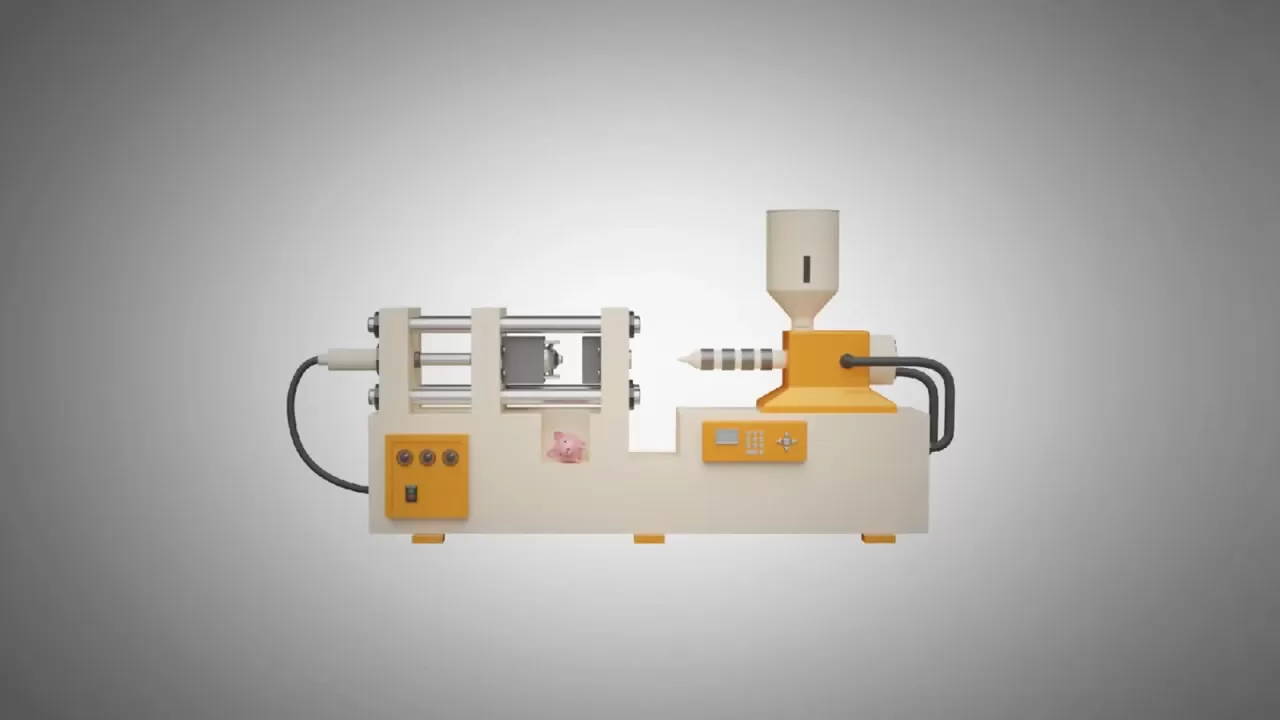

Find the Right Partner

The selection of a proven plastic manufacturing firm is important. Find business partners who are competent in injection molding, thermoforming, or CNC plastic fabrication, and who have experience in your industry. Effective communication and schedules make the production process run smoothly, and technical skills make you perfect every detail to perform and look good.

Growth by Integration

To maximize on custom plastics, coordinate your design, engineering and marketing teams. Use customer feedback and performance data to improve every iteration. This strategy transforms plastic products into strategic resources, making the products easier to use, maintain brand loyalty, and increase profitability.

Final Thoughts

Custom plastic products enable companies to be innovative, optimised, and differentiated. When you design and build unique, strong, affordable solutions to your specifications by customizing materials, designs, and production processes to meet your unique requirements, you produce unique designs that satisfy customers and enhance your brand identity.