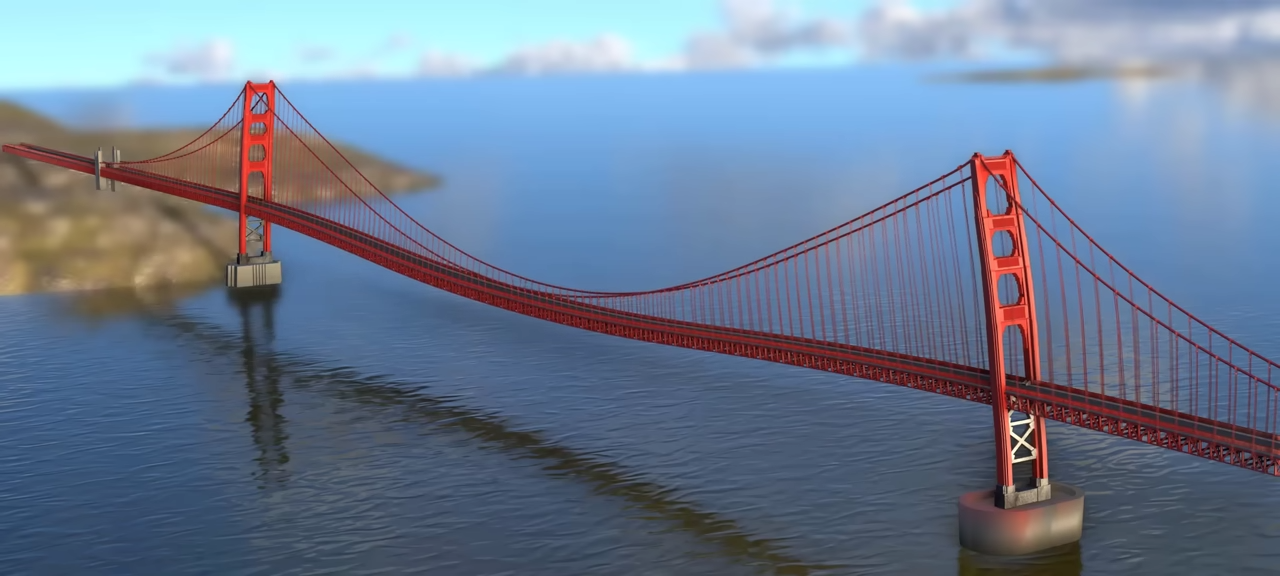

The Golden Gate Bridge stands as one of the most iconic structures in the world, a testament to the brilliance of engineering and human ingenuity. Spanning 2.7 kilometers across the treacherous waters of the Golden Gate Strait, this suspension bridge was an unprecedented challenge when it was first conceived. With its stunning International Orange color, soaring towers, and intricate cable system, it remains one of the greatest feats of civil engineering to this day. Let’s dive into the fascinating engineering behind the Golden Gate Bridge.

Why a Suspension Bridge?

The location of the Golden Gate Bridge presented numerous challenges for engineers. The Golden Gate Strait is characterized by:

- Strong tidal currents

- Deep waters (over 300 feet in some areas)

- Heavy fog and high winds

- Frequent earthquakes

Given these conditions, conventional bridge designs, such as beam bridges and arch bridges, were ruled out. Beam bridges required multiple piers, which would obstruct shipping lanes, while arch bridges would require massive support structures, making construction impractical. The suspension bridge design was the perfect solution, offering a long-span, high-clearance structure that could withstand the environmental challenges of the area.

The Genius of the Suspension Bridge

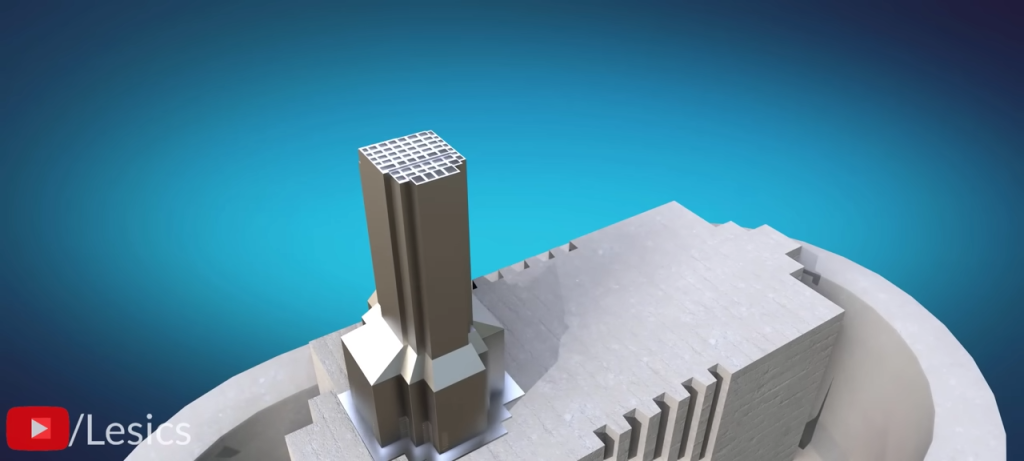

A suspension bridge consists of several key components:

- Towers – Support the entire structure by anchoring the main cables.

- Main Cables – Bear the load of the bridge and distribute it across the towers.

- Suspender Cables – Hang from the main cables and hold the roadway deck in place.

- Anchorage Systems – Secure the main cables to the land at both ends.

In the Golden Gate Bridge, the main cables stretch between two towering 746-foot tall pillars, distributing weight across the anchorage systems at both ends. These cables are composed of 27,572 steel wires, each meticulously spun into place, forming one of the strongest bridge cable systems ever built.

Structural Stability and Engineering Challenges

The sheer scale of the bridge required innovative solutions to ensure stability and longevity:

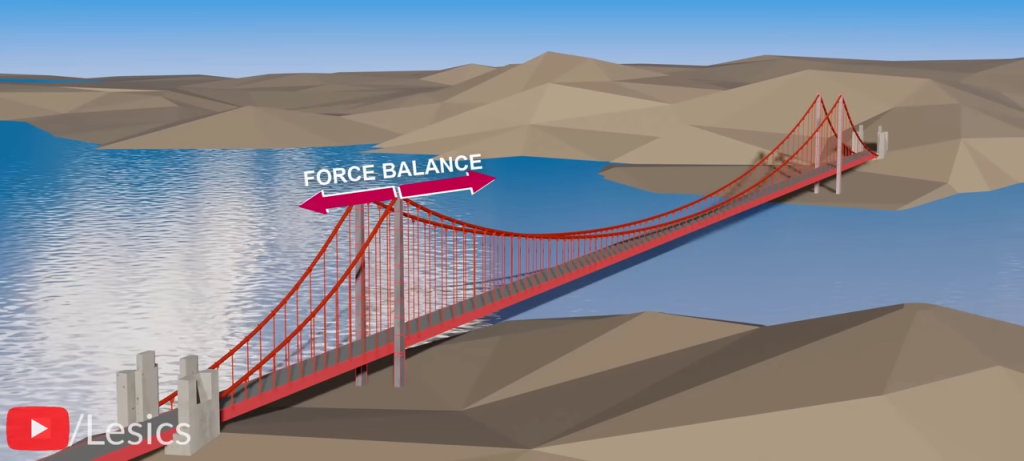

1. Preventing Tower Collapse

Without proper support, the towers would bend inward due to the enormous tension of the cables. Engineers countered this by extending the cables to anchorage systems on solid ground, balancing the forces acting on the towers.

2. Overcoming Wind and Fog Challenges

The Golden Gate Strait is known for its powerful winds. The suspension design allows the bridge to flex and sway with the wind instead of resisting it, preventing structural failure. The bridge can sway up to 27 feet without breaking!

3. Dealing with Thermal Expansion

Temperature changes cause steel and concrete to expand and contract. To accommodate this, expansion joints were installed in the roadway deck. These joints allow sections of the bridge to shift slightly, preventing cracks and structural damage.

4. Ensuring Safety During Construction

The bridge’s construction (1933-1937) was an engineering feat in itself. To protect workers from falling, a safety net was installed beneath the bridge, saving 19 lives. The bridge’s prefabricated steel sections were brought in via ships and assembled on-site using rivets and cranes.

Engineering Innovations in Construction

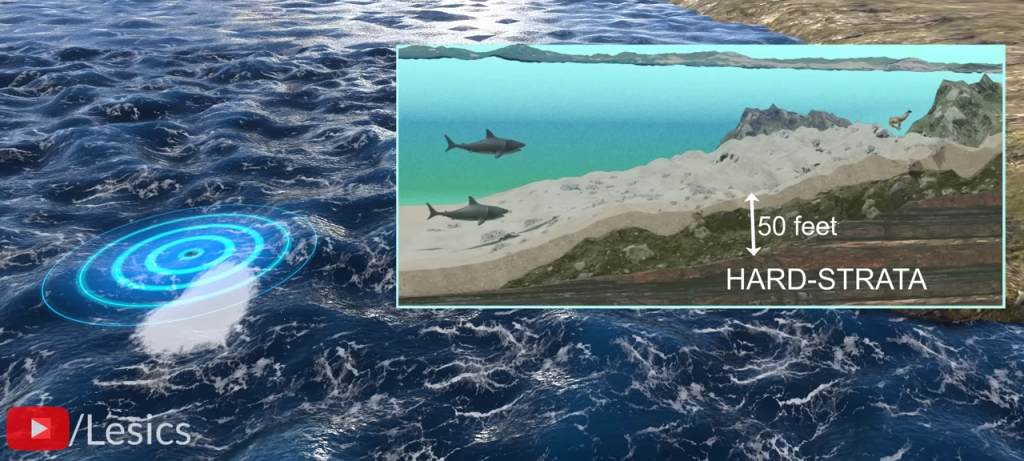

Building the South Tower on a Deep Seabed

The South Tower foundation posed a significant challenge, as it had to be built on the seabed 50 feet below water. Divers used explosives and heavy machinery to clear the seabed before constructing massive reinforced concrete piers. A clever fender wall system was designed to protect the foundation from strong ocean currents.

Creating a Strong Yet Economical Tower Design

A taller tower results in lower cable tension but increases construction costs. Engineers optimized the tower height to 746 feet, ensuring both strength and cost-effectiveness.

The 50th Anniversary Incident: A Test of Strength

On its 50th anniversary in 1987, over 300,000 people crowded onto the bridge, far exceeding its expected load. The deck sagged by nearly 2 meters, but the bridge held strong, proving the incredible resilience of its design.

A Legacy of Engineering Excellence

The Golden Gate Bridge remains one of the most photographed and visited landmarks in the world. Beyond its beauty, it stands as a symbol of engineering mastery, combining innovation, strength, and functionality in a way that was revolutionary for its time. Even after nearly 90 years, it continues to inspire engineers and travelers alike, proving that great engineering is truly timeless.